GSDG’s plant is designed to efficiently treat hazardous steel dust supplied from the Steel industry using Waelz Kiln Technology.

Zinc-coated galvanized steel scrap is the most widely used feedstock for Electric steel making. World crude steel production is expected to reach over 2 billion metric tons by 2030 of which Electric steel making will be 30% of the total steel making production (As per the World Steel Association website).

| Average growth rates & per annum | |

|---|---|

| Year | World |

| 1955-60 | 5.1 |

| 1960-65 | 5.6 |

| 1965-70 | 5.5 |

| 1970-75 | 1.6 |

| 1975-80 | 2.2 |

| 1980-85 | 0.1 |

| 1985-90 | 1.4 |

| 1990-95 | 0.5 |

| 1995-00 | 2.5 |

| 2000-05 | 6.2 |

| 2005-10 | 4.6 |

| 2010-15 | 2.5 |

| 2015-20 | 3.0 |

| 2020-21 | 3.8 |

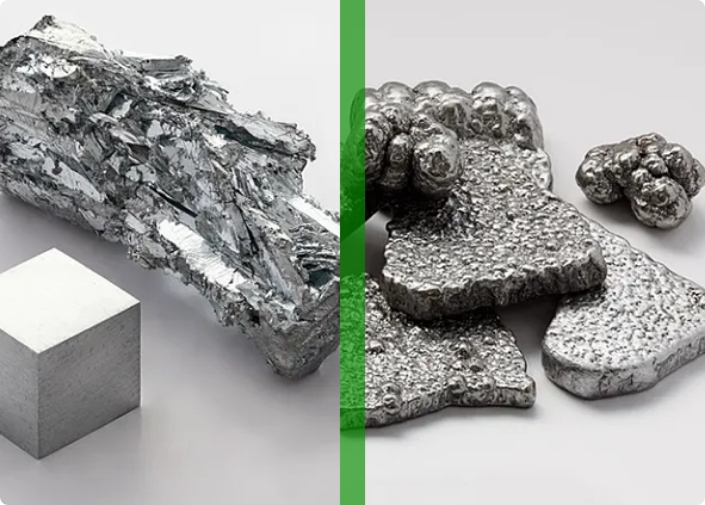

GSDG recycles the Steel dust from the Electric steel making process that is captured in the off-gas baghouse at its plant. GSDG collects and safely transports to its facility where it fully recycles the Steel dust.

Internationally, the Steel dust is considered a hazardous waste due to the presence of heavy metals in the dust.

GSDG economically recycles the Steel dust in a viable way and contributes with its recycling process to the reuse of zinc back into the Steel industry. In so doing it actively takes part in the circular Zinc economy by preserving the natural resource.

GSDG provides steel companies with a viable option to landfilling and promotes the environmental laws prescribed by the environmental regulations.

Copyright @ GSDG Powered by Mindfield Digital

$$$$